Black Hawk Trading & Contracting maintenance facility located in Misfa Industrial Area is providing below listed services to its valuable clients:

BLACK HAWK

Repair Facility

SAFETY

Do it for LifeLocal SME

Riyadha CompanyDownload PDF Profile

Electromechanical Repairs and Maintenance Facility ProfileOur Services

- Rewinding of AC & DC Motors

- Rewinding of LT & HT Alternators

- Maintenance & Servicing of Motors & Alternators

- Electromechanical Repair & Maintenance Services

- Machining & Mechanical Works

- Industrial Panel Repair Works

- Fabrication Services

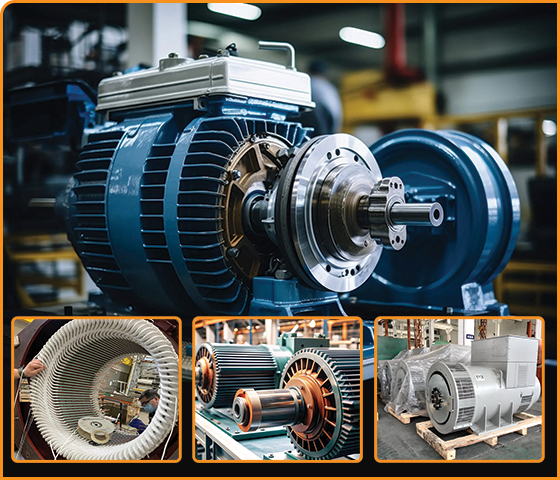

Rewinding of AC & DC Motors:

Rewinding of AC and DC motors is the process of repairing or replacing the windings (coils of wire) in the motor to restore it to its full functionality. Over time, motor windings can wear out, burn, or deteriorate due to overloading, high temperatures, or electrical faults. Rewinding is often the most cost-effective way to repair the motor and prolong its life.

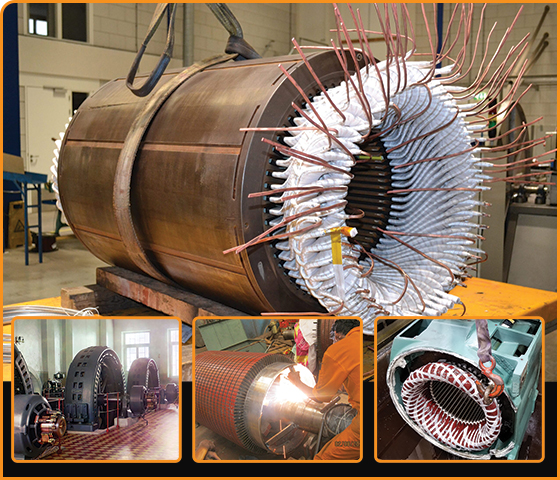

Rewinding of LT & HT Alternators:

Rewinding of LT (Low Tension) and HT (High Tension) alternators involves the process of repairing or replacing the windings in the alternator to restore its full functionality. The windings in alternators are critical for converting Mechanical Energy into Electrical Energy, and any damage to them can result in poor performance, overheating, or even complete failure of the alternator. The rewinding process for both LT and HT alternators involves several steps, though there are some differences based on the voltage class of the alternators.

Both LT and HT alternators require skilled professionals and the proper equipment to ensure that the rewinding process is done correctly, ensuring the longevity and reliability of the alternator once it’s put back into service.

Maintenance & Servicing of Motors and Alternators:

The maintenance and servicing of motors and alternators are critical for ensuring their longevity, efficiency, and safe operation. Motors and Alternators, whether AC, DC, or high/low tension, require periodic checks and care to prevent breakdowns and enhance performance.

Proper and regular maintenance of motors and alternators can help minimize downtime, increase efficiency, and extend their lifespan. Timely servicing and monitoring can also help identify problems early, preventing more significant and costly repairs in the future.

Electromechanical Repair & Maintenance Services:

Electromechanical repair and maintenance services cover a wide range of tasks related to the repair, servicing, and upkeep of electromechanical systems, which involve both electrical and mechanical components. These systems include motors, alternators, transformers, pumps, generators, and various industrial machinery. Regular repair and maintenance of these systems are essential to ensure their optimal performance, avoid breakdowns, and extend their lifespan.

Electromechanical repair & maintenance services cover everything from troubleshooting, part replacement, rewinding, routine inspections, lubrication, and calibration. Implementing a proactive maintenance plan for electromechanical systems minimizes downtime, optimizes performance, and improves the safety and efficiency of operations.

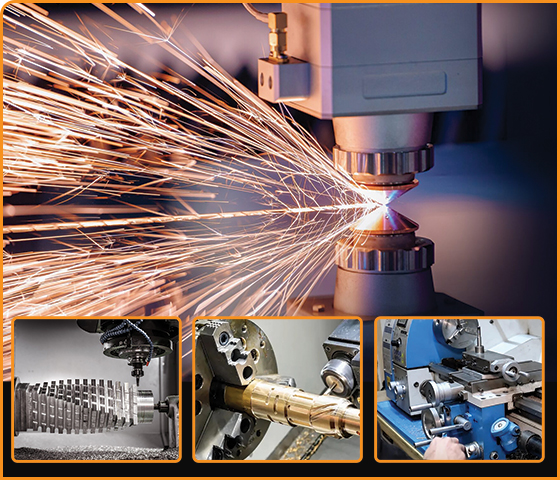

Machining & Mechanical Works:

Machining and mechanical works are essential services in most of the industries, involving the process of shaping, assembling, and maintaining mechanical components to meet precise specifications. These services are often required for manufacturing, repairing, and maintaining equipment such as machines, engines, pumps, motors, and many other mechanical systems.

Machining focuses on precise shaping, cutting, and finishing of materials, while Mechanical works encompass a broader range of activities, including the assembly, installation, and repair of mechanical systems. Both types of work contribute to ensuring that equipment operates efficiently, safely, and at full capacity, helping to extend the life of industrial machinery and systems.

By providing skilled machining services and mechanical support, industries can ensure optimal performance, reduce operational downtime, and lower long-term costs associated with machinery failure or inefficiency.

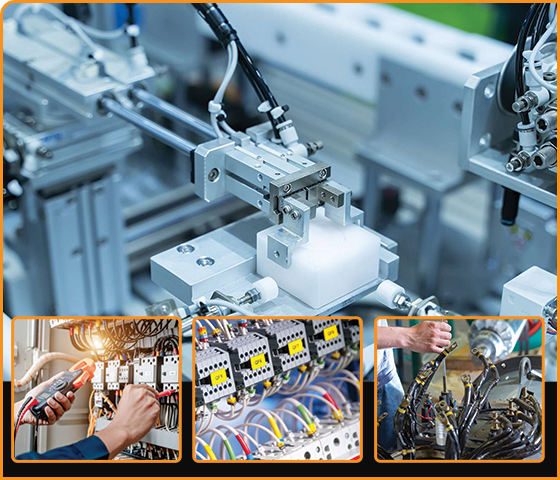

Industrial Panels Repair Works:

Industrial panels repair works involve the maintenance, troubleshooting, and repair of electrical control panels, distribution panels, motor control centers (MCCs), and other industrial electrical enclosures. These panels are crucial for the control and distribution of electrical power within industrial facilities, machinery, and equipment. Proper maintenance and repair including base structure of these panels are essential for ensuring the safety, efficiency, and reliability of electrical systems in industries like manufacturing, oil and gas, power generation, and many more.

Industrial panel repair works involve diagnosing and fixing faults, replacing damaged components, and ensuring that panels operate efficiently, safely, and in compliance with regulations. Through regular inspection, maintenance, and timely repairs, industries can ensure that their electrical control systems continue to function reliably, minimizing downtime and ensuring worker safety.

Fabrication Services:

Fabrication services involve the creation, manufacturing, and assembly of metal structures and components from raw materials. These services are essential in a wide variety of industries, such as construction, manufacturing, oil and gas, power generation, automotive, aerospace, energy, and many more. Fabrication encompasses a wide range of processes, including cutting, welding, bending, machining, and assembly of metal parts or structures to meet specific customer requirements.

Fabrication services are essential for creating custom metal structures, components, and systems across a wide range of industries ensuring that industries can produce high-quality and reliable products as per customers & clients requirements.